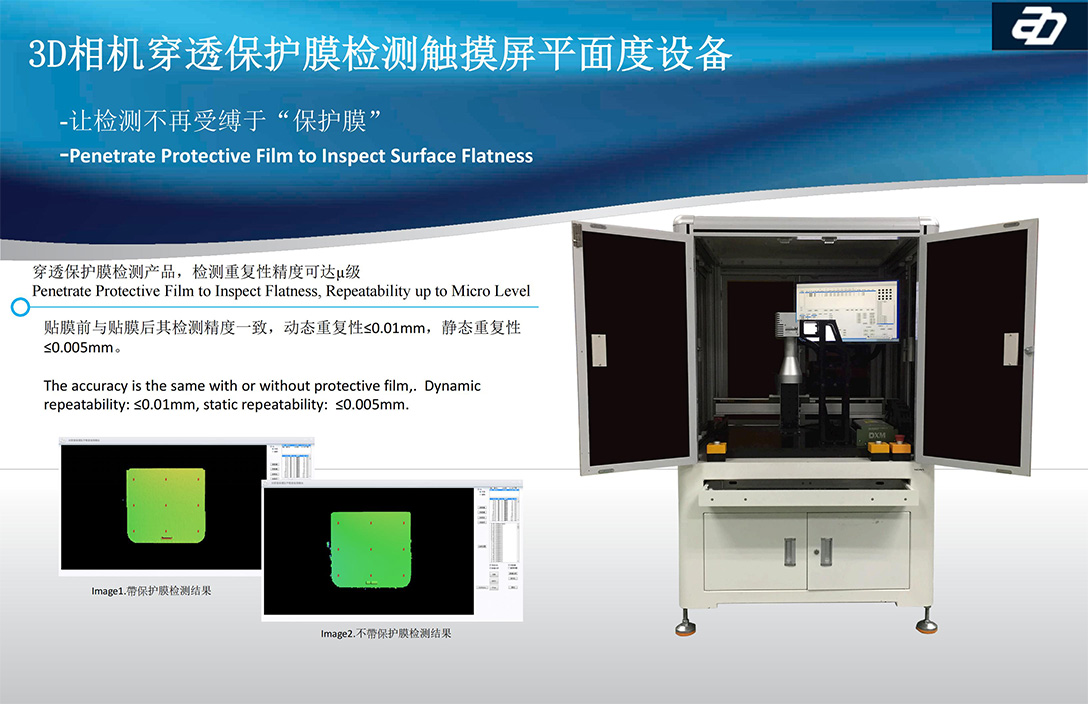

| 3D camera penetrates the protective film to detect the flatness of the touch screen device |

| Machine name |

3D camera penetrates the protective film to detect the flatness of the touch screen device |

| Detection object |

Glass (2D/3D) / metal parts / plastic parts / touch screen (and glue) and other materials |

| Test content |

Detect the flatness of the touch screen through the protective film |

| Overall dimensions |

1000*1000*1620mm |

| weight |

660kg |

| Effective itinerary |

X axis 410mm, Y axis 410mm, Z axis 100mm |

| Targeting |

Fixture positioning |

| Operation method |

Manual manual operation/single station or multi-station automatic detection (can be customized according to requirements) |

| Overall positioning accuracy of the machine |

3μm |

| Measured product size range |

150mm(L)*120mm(W) (can be customized according to requirements) |

| Main parameters of the detection system |

3D camera:

1. Model: CHRocodile FSS; 2. Scanning range: 80mm in diameter; 3. Effective measuring range: 200+0.5mm; 4. Fastest sampling frequency: 70KHZ; 5. Non-contact scanning; 6. Horizontal resolution :21um; 7. Spot size: 42um; 8. Numerical aperture: 0.015mm; 9. Measuring angle: 90+/-1 degree; |

| Detection time |

5s |

| Detection repeatability accuracy (static) |

5um |

| Main configuration |

a.

Fangtong welding lower frame + aluminum profile upper frame + large iron plate + XY linear motor module + product fixing fixture b. IT: 1 computer host (1*EH-7i7) + 1 display (VA229N) +1 set of keyboard and mouse set (MK-200) |

| Use environment |

a. Temperature: 22℃±2℃;

b. Humidity: 55-65%;

c. Vibration: The floor vibration of the installation site, when the vibration is below 10Hz, the amplitude must be below 2μP-P. When the vibration is between 10Hz~50Hz, the acceleration must be below 0.4qal. It is recommended that the installation place be as far away as possible from vibration sources such as press machines or large truck passages to ensure the accuracy of the machine;

d. Power supply:

1.220V AC, 50HZ; (single phase: L+N+PE) 2. Power: <2000W; 3. The power socket is a triangle plug; 4. The power supply needs to be grounded;

e. Air source (when a vacuum system is required):

1. Compressed air greater than 6 kg, the air needs to be dried and filtered. There is no model requirement for the model of the dryer and filter, just ensure that the filtration density is less than 1μ;

2. Ensure stable air pressure;

3. Ensure that the consumed air flow is greater than 630L/min;

f. Product discharge connection (the following method can be used if necessary Do connection):

OK is connected to the conveyor belt for manual visual inspection, and NG products are directly connected to the distribution box. |

| * The detection accuracy that can be achieved due to different materials of products and different surface treatment processes will vary, and the actual measurement results shall prevail. |

Multi-station detection plus scanning laminating machine

Multi-station detection plus scanning laminating machine Height difference and gap measurement machine

Height difference and gap measurement machine Multi-Functional Ring Track Inspection Machine

Multi-Functional Ring Track Inspection Machine 3D Array Camera Inspection Machine

3D Array Camera Inspection Machine High Speed & Precision Inspection Machine with 3D Camera

High Speed & Precision Inspection Machine with 3D Camera Touchpanel Flatness Inspection Machine

Touchpanel Flatness Inspection Machine Type-C Inspection Machine

Type-C Inspection Machine Flatness Inspection Machine

Flatness Inspection Machine Mental Frame Inspection Machine

Mental Frame Inspection Machine Sweat and Ocean Constant Temperature Humidity Machine

Sweat and Ocean Constant Temperature Humidity Machine Fully Automation Modular Inspection Machine

Fully Automation Modular Inspection Machine Automatic precision adjustment resistor machine

Automatic precision adjustment resistor machine Flatness testing machine

Flatness testing machine Drum paper F0 test machine

Drum paper F0 test machine Miniature Drum Paper Sound Film F0 Tester ECL-01

Miniature Drum Paper Sound Film F0 Tester ECL-01 Bullet Wave Tester I-009P

Bullet Wave Tester I-009P