0769-83101070

18128032987

18128032987

- Home

- Computer Division

-

Product

-

Multi-station detection plus scanning laminating machine

Multi-station detection plus scanning laminating machine -

Height difference and gap measurement machine

Height difference and gap measurement machine -

Multi-Functional Ring Track Inspection Machine

Multi-Functional Ring Track Inspection Machine -

3D Array Camera Inspection Machine

3D Array Camera Inspection Machine -

High Speed & Precision Inspection Machine with 3D Camera

High Speed & Precision Inspection Machine with 3D Camera -

Touchpanel Flatness Inspection Machine

Touchpanel Flatness Inspection Machine -

Type-C Inspection Machine

Type-C Inspection Machine -

Flatness Inspection Machine

Flatness Inspection Machine -

Mental Frame Inspection Machine

Mental Frame Inspection Machine -

Sweat and Ocean Constant Temperature Humidity Machine

Sweat and Ocean Constant Temperature Humidity Machine -

Fully Automation Modular Inspection Machine

Fully Automation Modular Inspection Machine -

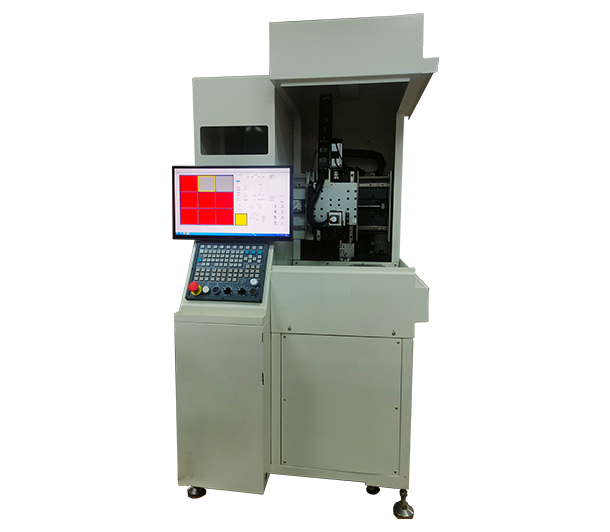

Automatic precision adjustment resistor machine

Automatic precision adjustment resistor machine -

Flatness testing machine

Flatness testing machine -

Drum paper F0 test machine

Drum paper F0 test machine -

Miniature Drum Paper Sound Film F0 Tester ECL-01

Miniature Drum Paper Sound Film F0 Tester ECL-01 -

Bullet Wave Tester I-009P

Bullet Wave Tester I-009P

-

- About

- News

- Patent

- Download

- Recruiting